Testing

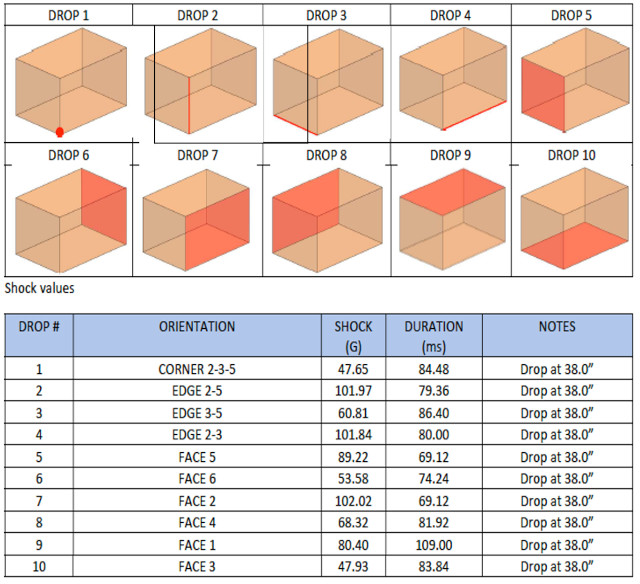

SPG’s product testing involves a systematic and agnostic evaluation of packaging materials, designs, and performance under various conditions to ensure customers’ products are delivered undamaged. Performed by our Detroit and Silicon Valley design teams, our testing protocol simulates real-world scenarios like storage, transportation, and handling to assess the durability of packaging designs. Our rigorous testing helps ensure product protection as well as product quality, safety, and regulatory compliance.

SPG’s packaging testing covers various aspects, including:

- Product Protection: Evaluating packaging design for damage, contamination, and degradation prevention.

- Compliance and Regulations: Ensuring packaging meets regulatory standards and industry guidelines.

- Durability: Assessing packaging’s strength and ability to withstand stress, impact, and vibration during handling.

- Environmental Conditions: Evaluating packaging resistance to temperature, humidity, and other environmental factors.

- Customer Experience: Assessing the ease of opening, closing, and handling of packaging for a positive customer experience.

- Cost Optimization: Identifying the most cost-effective packaging materials and designs while maintaining product integrity.

- New Product Development: Testing new packaging concepts and materials to ensure they meet performance requirements.